Custom Carbon Fiber Tubes: Tailored to Your Needs

•

Current diameter range 7" to 27.4" (so far) with lengths up to 90"

•

Solid wall tube wall thickness from 0.05" and up

•

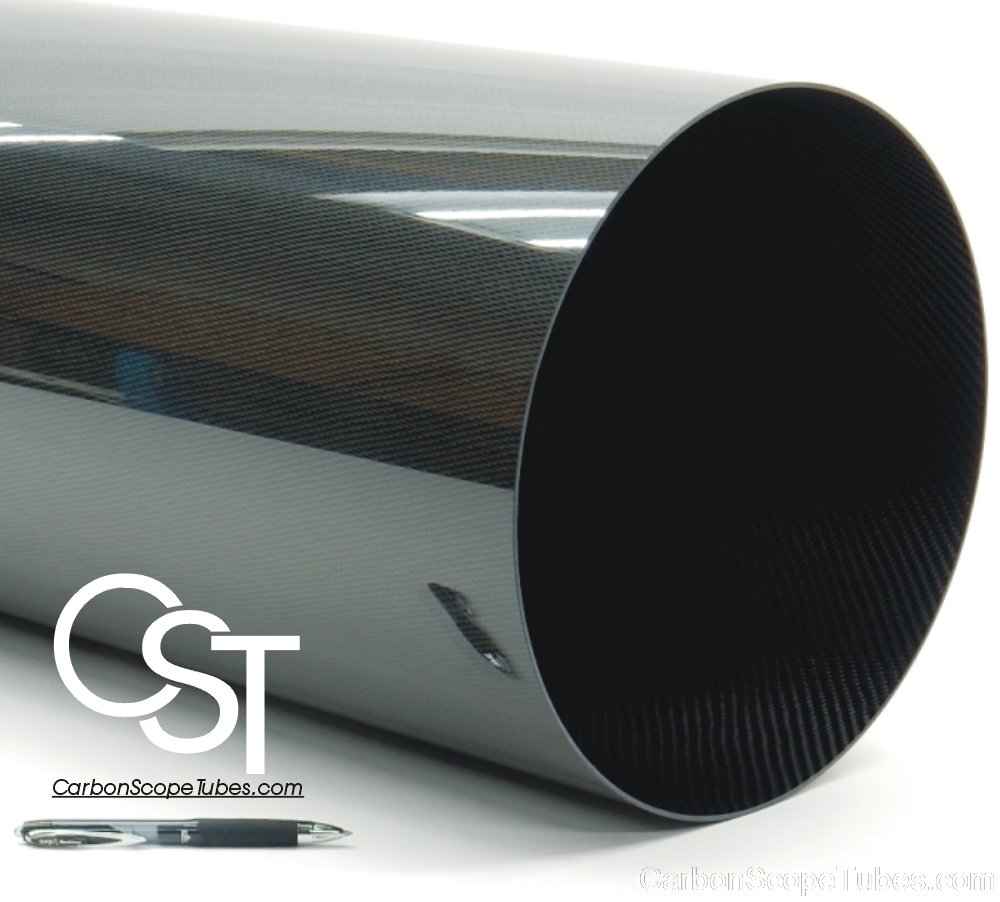

Two exterior finishes available; smooth sanded or polished UV-blocking clear-coat

•

Tube interior is naturally glossy, flat black painting is available

•

Cutting, drilling, milling, bonding available

•

Telescoping tubes and tapered tubes available

Urethane Clear-Coat Finish (Optional)

Our Premium carbon fiber tubes are coated with a two-part, automotive-grade urethane that is clear and glossy. To ensure the best quality, the clear coat is baked until it fully cures, after which it is polished to a mirror-like finish.

We specifically use a clear coat with excellent UV-blocking agents to minimize the impact of UV radiation on the epoxy resin. Other carbon fiber tubes without UV protection can yellow and degrade over time, which is why it's important to choose a tube with UV protection.

Ultra Flat Black Tube Interior (Optional)

We have spent a lot of time researching and testing different paints for our carbon fiber tubes to ensure they have excellent bonding to the material and a lower reflectivity than any paint we've ever tested. Our proprietary paint treatment is standard on our Celestron C-14 upgrade tubes and optional on all custom tubes. We have conducted extensive testing, including submerging the tubes in water at various temperatures for up to two weeks, to ensure the paint holds up and maintains its flat black appearance.

Hole Drilling and cutting (Optional)

Drilling a hole in our carbon fiber tubing is a quick process that takes only about 5 seconds with a high-quality drill bit. However, proper layout and positioning of the holes can be a time-consuming task that may take several hours. If you require custom hole layouts in your carbon fiber tubes, there will be an additional charge for this service. Rates vary depending on the number of holes and the complexity of the layout. A detailed drawing will be required for quoting.

Alternatively, you can choose to drill the holes yourself during the assembly process of your custom scope. Carbon fiber tubes can be drilled using any sharp drill bit in a power hand drill. However, for larger holes, such as those required for focusers, it is recommended to use a good-quality, fine-tooth hole saw to ensure a clean cut. With these simple tools, you can easily customize your carbon fiber tube to meet your specific needs.

Get a quote today!

Carbon Fiber Telescope Tubes: Stronger, Lighter, Better

How does a carbon fiber tube upgrade improve Astrophotography?

Stay Focused

For applications where maintaining image quality in changing temperatures is crucial, as in astrophotography, a carbon fiber optical tube is a reliable solution. Aluminum tubes tend to shrink as temperature decreases, which will cause the primary and secondary mirrors to move closer together, resulting in a shift of the focal plane off the imaging chip and producing blurry images. Carbon fiber tubes, on the other hand, have a significantly lower shrink rate, which allows for longer imaging periods without the need for frequent refocusing. In fact, carbon fiber has a shrink rate that is at least one-fifth that of aluminum, which can result in a five-fold increase in the amount of time that can be spent imaging before refocusing is required. However, it is important to note that focus may still need to be adjusted when changing filters and that temperature changes can vary from night to night.

"Before upgrading my C-11 to a carbon fiber telescope tube, I had trouble with narrowband exposures of over 45 minutes on a typical Michigan night, as the temperature can easily drop 2 degrees per hour. In just these few minutes, my aluminum OTA would shrink enough to defocus my system. However, with the carbon fiber tube upgrade, I'm now able to image for longer periods without needing to re-focus. As you can see in the M-27 image I posted here, I used a series of 90 minute H-alpha sub-exposures (plus RGB). I've even been able to take 120 minute narrowband exposures, which would have been impossible for me without the carbon fiber tube upgrade." ---Frank

Lose Weight

Carbon fiber tubes offer a weight savings of around 40% over comparable aluminum tubes. While weight may not be a significant factor for a typical SCT, it can make a huge difference for longer telescope tubes like an RC, Newtonian, or Classical Cassegrain. Additionally, if you're already pushing your mount (or your own physical limits) to the max, saving a few pounds can make a big difference. For example, switching to a carbon fiber tube on a C-14 can save up to 3 lbs, which can be a noticeable improvement in terms of ease of use and overall performance.

Look Great!

Nothing has a better "wow factor" than a finely finished carbon fiber tube. Up close, it looks like a hi-tech 3D snake skin with amazing depth. The unique look of a carbon fiber telescope tube is a clear sign that you take your astronomy equipment seriously and value quality and attention to detail.

Get a quote today!

Large Carbon Fiber Tubes: Applications Beyond Astronomy

•

Structural housings for telescopes, metering tubes, and other optical instruments

•

RF shielding for electronic assemblies

•

Medical imaging component housings

•

Capture Hoods for HVAC airflow measurement

•

Whenever your project requires light weight, high strength, thermal stability, etc.